Plast Eurasia 2022 – International Exhibition / Istanbul – Turkey

Polypropylene (PP) was introduced to the market in the late 1950s and is the most widely used economic-commercial thermoplastic that has grown and developed the fastest in the world. PP is a polymer with multiple and diverse applications that has been used in producing fibers, films, household appliances, and car bumpers. In many applications, PP has replaced other materials such as glass fibers and thermoplastics reinforced with minerals and metals. PP is synthesized by polymerizing polypropylene monomer with a titanium-based catalyst. To start the polymerization reaction, a secondary auxiliary catalyst (triethylaluminum) is added to the reaction medium and hydrogen is used to control the molecular weight of the polymer inside the reactor. This reaction is done using a slurry process or a gas type process. There are three structures of PP: isotactic, syndiotactic and atactic. The main structure of PP is isotactic semi-crystalline material. This structure has good mechanical properties, such as stiffness and tensile strength. These properties can be enhanced by using nucleating agents or fillers such as talc, calcium carbonate or glass fibers. Syndiotactic PP is produced through polypropylene monomer units that are alternately connected to each other in a head-to-tail manner. This structure is more flexible than the isotactic, but it has better impact resistance and more clarity.

Atactic PP (hard wax-amorphous monomer) is a by-product of the PP production process. This polymer is used in tarring the surface of roofs and making adhesives in the shoe industry.

All three PP structures are very sensitive to oxidation caused by the presence of tertiary hydrogen. PP is stabilized and resistant to degradation and thermal decomposition by adding type 1 and type 2 antioxidants. Special neutralizing agents are also used to stabilize small amounts of chloride ash produced during the process. Other special additives are also used, such as antistatic agents, slip agents, and UV stabilizers. PP is sold commercially as homopolymers, random copolymers, or impact copolymers. Its physical properties are changing from a polymer with high strength and stiffness to a flexible polymer with lower strength but greater toughness. PP homopolymer has the highest melting point and hardness along with a wide range of melt flow properties.

Copolymers with small amounts of ethylene in their structure have lower crystallinity are flexible, have a lower melting point, and show improved and better impact resistance properties.

Impact-resistant copolymers are copolymerized and produced through the addition of ethylene in the polymerization reactor. Copolymer (ethylene) acts as a plasticizer and process aid and is uniformly dispersed throughout the homopolymer matrix to obtain a heterophase polymer, i.e. two heterogeneous phases. This copolymer has very high impact resistance even at low temperatures. Copolymers with high impact resistance are prepared through pre-blending of copolymer, additives and EPDM rubber.

The chemical structure and general properties of PP homopolymer are as follows:

PP is a light material with a specific mass lower than water obtained from the polymerization of propylene gas. PP is resistant to moisture, oils and common solvents and melts at about 170°C.

Today, PP has many types with different molecular weights and additives to be used in appropriate applications. PP is solid at room temperature. According to the order of its molecules, PP shows different properties.

PP is classified in the family of semi-crystalline thermoplastics. Isotactic and syndiotactic PP have the ability to crystallize while atactic PP has an amorphous structure.

The main parameters that determine the properties of this polymer are molecular weight and its distribution, polymer melt flow index, isotacticity percentage, as well as polymerization process and type and amount of additives.

For the production of most of the common medium weight fibers, the molecular weight is in the range of 200,000 to 350,000.

PP has a high degree of crystallization, which reaches up to 70%. PP is sensitive to ultraviolet radiation and is destroyed. To prevent this unwanted process, UV light stabilizers are added.

PP is one of the polymers with diverse performance that is used in the production of various plastic parts as well as in the fiber industry. Due to its high crystallinity and non-polar aliphatic structure that does not contain any active agent, this polymer cannot be dyed by conventional methods. Therefore, the polymer mass dyeing method is used to produce colored fibers, which itself has limitations in terms of diversity, color transparency, the possibility of dyeing in each stage of the production of textile products. Therefore, many efforts have been made in the field of producing modified PP fibers that can be dyed with conventional methods and many patents have been registered. Most of these modifications are based on the addition of factors such as PP (in the form of linking on the molecular chain) to improve the absorption of dyes. However, modified PP fibers have not yet been supplied to the market.

Advantages of PP

• Lighter stability with low density

• High melting point

• End use temperatures around 212°F

• Good chemical resistance to hydrocarbons, alcohols and non-oxidizing reagents

• Good fatigue resistance (in hinged doors or caps)

PP can be processed and shaped through all the special thermoplastic resin process methods such as injection molding, compression molding, blow molding, extrusion, film casting and thermoforming.

Disadvantages and limitations of PP

PP is destroyed by UV. It is Flammable, but commercial FR (flame retardant) grades are available. PP is attacked by chlorinated and aromatic solvents.

Applications of PP

PP is processed by various methods such as injection molding, blowing, rotation and extrusion, which depending on the type of use can contain additives, anti-oxidation, UV stabilizers, anti-static materials, nucleating agents, pigments, fire-retardants, fillers, etc.

PP is mostly used in the injection molding process and ranks second in the fiber industry. The consumption of PP fibers has increased in the last decade and it is the second most used synthetic fiber after polyester. PP has been marketed in the form of single fibers and threads for the textile industry. Very fine fibers of PP are used for the production of thermobonding and spinning. Medium fineness fibers are used for spinning and production of knitting and tricot yarn, and its thick fibers are used for the production of floor coverings. The favorable properties and cheapness of these fibers have led to their widespread use in the field of non-woven textiles in structures. PP filament yarn is mainly produced as BCF (Bulk Continuous Filament) yarn, which is used in the production of floor coverings. Its fine yarns are also produced for various applications, especially as industrial yarns, but their use in textiles is limited due to the impossibility of dyeing and their weak texuring ability with the common methods of texuring fine yarns (virtual warping method).

This polymer is used in the automotive industry, interior decoration, propellers, car flooring, packaging and fiber industries. Carpets, artificial grass covers, anti-rot rope and fishing nets are other applications of polypropylene.

Flexible packaging films and biaxially oriented packaging films.

Single strand oriented and stretched and thin strips for textiles, carpet weaving, insulated medical fabrics and backings of woven carpet.

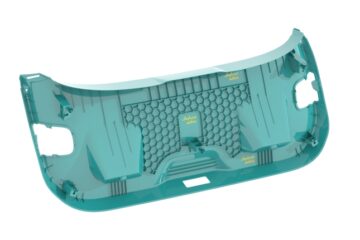

Interior components, bumpers, spoilers, exhaust systems, under-hood components, wheel head protective hose

Sanitary products, household goods, medical trays, strainers , and hollow containers.

Caps, upper caps, sprays, rigid and semi-rigid packaging, videocassette frames, toys, electrical hardware, household appliances and their components, furniture for field trips and outside the city in the open air, suitcase, etc.

Molded bottles by injection blow molding method with excellent rigidity, impact resistance and transparency.

Chemical structure and general properties of acrylic are as follow:

PMMA Properties

Acrylics are composed of polymers and copolymers whose main monomers belong to the two families of ester-acrylates and methacrylates. Transparent and hard acrylic sheets are made from methyl methacrylate, while extrusion and molding resins are made in a continuous solution of methacrylate copolymerized with a small percentage of acrylates or methacrylates.

Methyl methacrylate is produced through a two-step process in which acetone and hydrogen cyanide are reacted to give acetone cyanohydrin. Then, this compound is heated with methanol in the presence of concentrated sulfuric acid to obtain methyl methacrylate monomer. Acrylic monomers are polymerized through free radical polymerization processes initiated by peroxide initiators and form poly (methyl methacrylate). A monomeric initiator which become active at higher temperatures causes a reaction to be progressed that is very intense and exothermic, so that the released heat must be somehow removed from the system.

Different formulations of plastics differ both in molecular weight and in basic physico-mechanical properties such as melt flow index (MFI), thermal resistance, and toughness. There are special formulations that create opaque surfaces or absorb or transmit UV light. They are also available in a full range of colored resins in transparent, semi-transparent (translucent) and opaque forms.

Commercial types of acrylic with high impact resistance are available for injection molding and extrusion. These types of compounds consist of a hard acrylic phase and an acrylic modifier as a soft phase. Acrylic polymers have excellent optical properties and resistance to weathering and environmental conditions. Colorless acrylic resin can transmit white light up to 92%. Acrylics show a very high resistance to sunlight and long-term contact with various elements.

The low strain optical coefficient of acrylics, combined with their ability to be molded under very low stress, make them an ideal material for making video discs. Extruded sheets of a commercially available impact-modified acrylic exhibit excellent thermoforming properties and can be stiffened with glass-reinforced polyester so that they can be used on the inside of bath tubs. The high flow type has the best transparency because it does not contain acrylonitrile (AN), which makes this polymer the most suitable for medical applications where clarity is most important.

Acrylic plastics can be cleaned with solutions of mineral acids, alkalis, and aliphatic hydrocarbons, but chlorinated and aromatic hydrocarbons and ketones will degrade acrylic plastics.

Advantages

Acrylic polymers, such as poly (methyl methacrylate), show excellent optical and weather-resistant properties, that is, when they are exposed to atmospheric conditions, they are highly resistant to weathering and environmental conditions (temperature, pressure, humidity or steam water). They are also available in a wide variety of colors of transparent, translucent, and opaque.

• Excellent optical clarity

• Excellent surface hardness

• Excellent tolerance to various weather conditions, excellent resistance to weathering and atmospheric conditions, high resistance to sunlight.

• Rigid and inflexible with good impact strength

• Excellent dimensional stability and low in-mold shrinkage

Disadvantages and limitations

Applications

The compounds deliver light weight, attractive aesthetics, and sustainability benefits for automotive interiors.

Sabic has introduced a specialized portfolio of Sabic PP compounds for foam injection molding (FIM). New mineral-reinforced Sabic PPc F9005, PPc F9007, and PPc F9015 grades can help deliver attractive aesthetics for visible automotive interior parts with complex geometries, such as door panels and trim, seat and trunk cladding, A/B/C/D pillar covers, and center consoles.

Unlike standard FIM materials, which typically exhibit surface defects, the new advanced PP compounds feature uniformly high surface quality similar to solid injection molded parts. Compared with solid components, foamed parts made with Sabic PP compounds offer significant weight savings that can help cut emissions. According to a cradle-to-grave life-cycle assessment study (pending third-party review), the advanced materials can help OEMs lower carbon dioxide (CO2) emissions by as much as 15%.

“The automotive industry continues to look for new weight-out strategies that can advance energy efficiency and sustainability goals,” said Sabic’s Abdullah Al-Otaibi, General Manager, ETP & Market Solutions. “Although foam injection molding produces desirable lightweight parts, manufacturers have been forced to sacrifice aesthetics . . . until now. We applied our extensive expertise in foaming technology to develop these new compounds to help resolve the issue of surface quality and open new application opportunities for foamed parts.”

Previously, the FIM process was essentially limited to non-visible parts, restricting its usefulness in automotive applications. Foaming can underperform in surface aesthetics — silver streaking, swirl lines and dimples are common defects. Sabic PP compounds for foamed interior parts deliver low-gloss textured (grained) surfaces with uniformly high quality and eliminate streaking and swirling. Talc filler in these grades acts as a nucleator that promotes the generation of finer bubbles, which contribute to a consistent surface appearance. For enhanced aesthetics, these grades are currently available in selected automotive interior colors. Custom coloring is also available.

Optimizing weight-out benefits

Weight reduction results with Sabic PP compounds depend on several factors, including the type of FIM technique used.

Short-shot molding, which uses the same tooling as an injection molded part, can reduce weight by up to 10%. Sabic PPc 9007 is formulated for short-shot FIM and low-impact applications.

Core-back molding, which requires part redesign and new tooling, can lower weight by as much as 30%. Both Sabic PPc 9005 and PPc 9015 grades are formulated for core-back molding and deliver medium stiffness and impact.

The choice between the short-shot and core-back techniques, with their different tooling requirements, also helps to determine whether FIM with Sabic PP compounds is cost neutral or delivers cost savings. Additional cost savings are possible through cycle time reductions from flow improvements inherent in FIM.

Another consideration is the foaming process, which can use chemical or physical agents. The new Sabic PP compounds are good candidates for use with chemical blowing agents, which are typically preferred for visible foamed parts. These agents are introduced to the molding machine in the form of a masterbatch, along with the plastic pellets, and activated during the melt phase to release gases for foaming.

Sabic fully supports its new PP compound portfolio with extensive expertise in foamed part design, development, and processing, as well as predictive engineering. For instance, the company can provide guidance on the selection of the appropriate chemical blowing agent for each grade. Sabic’s technical team will collaborate with customers to achieve desired aesthetics at the lowest possible part weight.

To drive future developments in polymer foams, Sabic operates a Foam Innovation Center in the Netherlands. This center, which is equipped with foam process capabilities as well as analytical equipment, enables the company to develop new foam solutions and technology innovations and collaborate with customers.

The new Sabic PP compounds have launched in Europe, with upcoming availability in the Americas and Asia/Pacific.

Source: https://www.plasticstoday.com/automotive-and-mobility/sabic-debuts-pp-compounds-foam-injection-molding

Introduction

Polyamides are high molecular weight polymers that have an amide group in their main chain which is considered as the main component of the polymer chain. The amide groups strongly adhere to each other and ensure high strength. These groups, which have become almost linear due to stretching, create strong hydrogen bonds with each other which are very strong.

Polyamides are classified into two groups according to their constituent monomers. 1) Polyamides that are prepared from the reaction of amino acids (AB) by the addition polymerization method. This method is used to prepare some AB type polyamides whose monomers are cyclic lactams such as ε-caprolactam or pyrrolidinone. 2) Polyamides that are formed from the condensation of bifunctional diamine and diacids that are called AABB type polyamides in which A indicates the amino group and B indicates the acidic group.

Aliphatic polyamides are named from the number that indicates the number of carbons in their constituent monomers. For AABB type polyamides two numbers are used. The first one refers to the number of diamine carbon atoms and the second one shows the number of diacid carbon atoms. Polyamide derived from ε-aminocaproic acid (6-aminohexanoic acid) or lactam is known as polyamide 6. Components with benzene rings are marked with a letter. For example, terephthalic and isophthalic acid are marked with T and I. Some authors also use TA and IA.

Linear polyamides are condensation products of bifunctional monomers. The hydrocarbon part between the amide groups may include branched or linear condensed hydrocarbons, aromatic rings or aliphatic rings, which can also include oxygen, sulfur and nitrogen. The hydrocarbon part used in the chain affects the flexibility of the chain and its structural arrangement, which is an important factor for the formation of the crystalline phase.

Aromatic polyamides are polymers in which an amide bond is placed between two aromatic rings. These polymers are prepared from the reaction of aromatic diamines with aromatic diacids in an amide solvent. Fibers with good heat resistance and high tensile strength and modulus are prepared from these polymers. Due to the unusual physical properties of aromatic polyamides, the general name aramid was chosen for them in 1974.

Aramid is a synthetic fiber made from long-chain polyamide in which at least 85% of the amide bonds (CONH) are directly attached to two aromatic rings.

In commercial aramids, 100% of amide bonds are connected to aromatic rings. With the creation of the new term aramid, synthetic fibers made from long-chain polyamide in which less than 85% of the amide bonds are directly attached to the aromatic ring were called nylon.

Properties

Polyamides comprise properties such as excellent toughness and impact resistance, excellent abrasion resistance, low friction coefficient, high tensile strength properties and optimal creep resistance, maintaining mechanical and electrical properties in a wide range of temperatures, excellent resistance to oils, greases, solvents and bases. These polymers can be processed through all special methods of thermoplastics.

Polyamide 66

Polyamide 66 is produced through condensation polymerization of adipic acid and hexamethylenediamine. The repeating unit of this plastic is as follow:

The molecular mass of polyamide 66 fibers is about (1500 to 13000) g/mol, while for the production of parts, the molecular mass of polyamide is usually higher than 24000.

Advantages of polyamide

• High impact resistance

• High hardness

• Abrasion resistance

• Flexibility

• Stability against many solvents and chemicals

Polyamides show very good resistance against petroleum substances and aliphatic solvents, but they are strongly affected by concentrated mineral acids at room temperature and alkalis at high temperature.

Polyamides are hard to catch fire and if they get out of the flame, they are self-extinguishing. Polyamide 66 fibers are resistant to the attack of insects such as willows.

If they are exposed to UV light, environmental factors and temperature of 130 oC during long-term operation, their color will fade and the mechanical properties will become weak and fragile. At a higher temperature, they are destroyed due to hydrolysis. The addition of light and thermal stabilizers slows down the effect of these factors on polyamides.

Research shows that polyamide parts that are used outside the room temperature should be stable and protected from sunlight, so an ultraviolet light absorber suitable for polyamides should be used in the polymeric compound. This can also be done by adding carbon black, so no significant change in their properties and performance in the long term at normal temperature.

Thermal properties of polyamide 66

In DSC thermogram, the melting phenomenon of polyamide 66 occurs around 264 oC, and at a temperature of 275 oCand above, this polymer is on the beginning of thermal degradation.

Another prominent feature of this plastic is the flexibility and good toughness of its fibers, which has made it widely used in the preparation of textiles, especially for women’s use. The permanent set of these fibers is occurred at 100 oC in which if they cooled slowly, the permanent crease will be created. Polyamide 66 maintains its mechanical properties up to 150°C, although conservatively, the temperature applied to this plastic (such as ironing) should not exceed 125°C.

Polyamides benefit from very good electrical insulation capabilities at low temperatures and low humidity, but these properties quickly disappear when the temperature rises or the humidity increases.

Increasing the methylene (-CH2) functional group in the acidic part of the polyamide chain makes this plastic have a lower melting range and less moisture absorption ability, at the same time it reduces its stiffness and weakens its mechanical properties.

Mechanical properties of polyamide 66

Polyamide 66 contains a set of excellent properties such as mechanical properties (high strengths, high toughness and excellent resistance to wear) and very good thermal and chemical properties.

Two widely used industrial polyamides 6 and 66, despite the differences in molecular structure, are relatively similar to each other in terms of most mechanical and chemical properties.

The most important mechanical properties of polyamides are expressed through the information obtained from measuring of tensile, bending, compressive, shear and hardness tests. The set of results obtained from these 5 tests provides a major part of the technical information needed for the designer.

Polyamide 66 has high tensile strength, high impact resistance, good dimensional stability at relatively high temperatures and good resistance to wear. It also can be lubricated, therefore it is used in the manufacture of bearings.

As a result of stretching, the degree of crystallinity of polyamide fibers increases and many of its mechanical properties are improved. The tensile strength of polyamide 66 fibers is high and reaches more than 8 gr/denier.

At first impression, samples made of polyamide 6 are softer than polyamide 66.

It is worth mentioning that after absorbing moisture, due to the increase in flexibility of polyamide, many of its mechanical properties decrease. Only the impact resistance increases.

The moisture absorption of polyamides, especially polyamide 6 and 66, causes a sharp decrease in their modulus, because the presence of water between the chains (especially in polyamides that have the ability to absorb high moisture) acts as a softening agent for them and causes a drop in the mechanical properties of polyamides. The moisture absorption has a very favorable effect on the electrical properties of these types of plastics.

Types of polyamide 66

Polyamide 66 contains a set of excellent properties and has the ability to be used in many applications and various processes. In the first and most important classification, the types of polyamides 66 are divided into six groups: homopolymer, copolymer, blend, improved, filled, and reinforced. Several varieties of glass fiber reinforced polyamide 66 are made in weight ratios of 10%, 15%, 20%, 30%, 33%, 40%, 50% and 60%.

With the aid of additives and with the aim of improving the properties and increasing the performance of polyamide 66, various types of this plastic have been offered to the consumer market such as the fire-resistant type, which is placed in V-0 site in accordance with UL 94 guidelines.

There is a type of polyamide 66, in which due to mixing with fluoroplastics the decrease in friction is appeared.

Another type of this plastic is offered in black color, which is reinforced against harmful environmental factors such as ultraviolet light. It is worth mentioning that in this type of polyamide the presence of carbon black acts as the ultraviolet light absorber.

There are varieties of polyamide 66 homopolymer that are made for the injection process with low viscosity and high melt flow rate.

Another type of polyamide 66 homopolymer is available in the market, which its high viscosity enables the preparation of thick parts in the injection process.

Another type of polyamide 66 made with molybdenum disulfide additive can show excellent resistance to wear.

Typical applications of polyamide

Transportation: Transportation represents the largest market for polyamides. Applications of unreinforced materials include electrical connectors, wire coatings and lightweight gears, windshield wipers and speedometers. Stone guards and trim clips have been used to protect the windshield of the car. Glass-reinforced polyamides have been used in engine fan shrouds, radiator heads, steering and brake of fluid reservoirs and valves, sensors, and fuel injectors. Mineral reinforced resins have been used in mirror tools and tire hub covers. A combination of glass and mineral materials is used in exterior parts such as fender extensions.

Electrical and electronic applications: Flame retardant polyamides, including those that are performed with UL-94V0 requirements, play a major role in the electrical goods markets (plugs, fasteners or connectors, coils, wiring harnesses, terminal blocks, and antenna mounting tools).

Home Appliances: Polyamides are used not only for components in electrical goods, but also for mechanical parts and tools, power tools, washing machines, and various small household appliances.

Special applications in telecommunications: Power amplifiers or radio/telegraph amplifiers, amplifier stations, and connectors.

Industrial applications: Including hammer or sledgehammer handles, lawnmower parts, non-greased gears, bearings, anti-friction parts and a wide range of applications requiring spring clips or mounting the load on the spring.

Food and textile processing equipment: Including pumps, valves, measuring devices, agricultural and printing devices, office and sales machines.

Consumer Products: Applications of tough and toughened polyamide include ski boots, roller skates and ice skates bases, racket sports equipment, bicycle wheels, kitchenware, toys, and photography equipment.

Polyamide films: These films are used in a wide range for packing all kinds of meats and cheeses, as well as in non-stick bags for cooking and frying food. They are also used as an enclosing coating for making small airplane wings made of thermosetting polymers.

Wire and cable coating: Polyamides are often used as a protective layer on the primary insulation layer.

Piping and piping materials: Polyamides are used to transfer special brake fluids, special fluids for refrigerators, or as an inner lining for flexible cables.

Extrusion: sheets, bars, and handle-like shapes in machining.

This application includes filter bags for hot gases coming out of the chimney, under-press fabrics in industrial presses such as use in the permanent press of the final stage of linen fabric and linen polyester clothes, ironing board cover and sewing thread for very fast sewing, insulating paper for electric motors, tubes made for wire insulation, and dryer belts for papermaking. Another application is as pressure sensors in fuel tanks.

• Flame-resistant materials:

This application includes industrial protective clothing such as welders’ clothing and other protective clothing, firefighter clothing, flight clothing for military pilots and mail bags, carpets, curtains, sofas, fabric and cargo covers, boat covers and tents.

• Materials with dimensional stability

Fire hoses, V-belts, and power transfer belts made with high modulus aramid fibers such as Namax are examples of this application.

• Cases with very high strength and high modulus

These materials are used in V-belts of cables, parachutes, bulletproof vests, rigid reinforced plastics, antenna components, electrical circuit boards, sports equipment, ship ropes, telephone and power line cables, and fiber optic cables. Other usage is as a substitute for fireproof cotton.

• Cases with special properties

This application includes the fabrication of hollow fiber permeable separation membranes used for seawater and saltwater purification.

• Application in automobile industry

Polyamide 6 and polyamide 66 are used in the automotive industry. This industry accounts for 25% of the global consumption of polyamides.

Polyamide 66, in addition to manufacturing engineering parts, is used to make textile fibers in a very large volume. Due to its linear structure and good physical and chemical properties, suitable fibers are obtained from this polymer. First, this fiber replaced silk and was used in textiles, then it was noticed in carpet weaving. In military purposes, it is used to prepare parachutes and life jackets.

The speedometer gear of odometers, and especially the timing gear (chain) of some cars, have been proven to be able to work for years if they are made of polyamide 66.

Woodworking hammer handles are made of polyamide 66 reinforced with glass fibers, which is a good substitute for wood.

Polyamide 6 and 66 are compatible with wool and cotton, so if they are added to natural fibers at a ratio of 30%, they increase their resistance to wear and tear, while also improving their ironability.

Polyamide 66 granules and powder must be dehumidified before the processing, otherwise the fabricated parts will be damaged in terms of mechanical properties and appearance.

The moisture absorbed by the granules of polyamides turns into steam during the molding process. The steam causes the hydrolysis of the polyamide, the reduction of the molecular mass, the loss of mechanical properties. It makes bubbles in the parts and causes some parts of the molded piece to be incomplete and creates adverse effects on the surface.

Moisture absorbed by polyamides changes and loses their good electrical properties. The electrical properties of polyamides are limited to their use in low frequencies because this plastic has polar groups.

The most important uses of polyamide 66, which is an engineering plastic, can be seen in these applications:

Replacement for metals in bearings, gears, rollers (cylindrical rollers) and cams

Power wires are coated with polyamide 66 because it provides a toughness, wear resistance, good insulation properties, and heat stability.

If multi-functional reagents such as triamines, tetraamines and trifunctional acids are used, it leads to the production of network polymers with major differences in their properties.

Product Introduction

Fiber reinforcements

Composites usually consist of a matrix to hold the reinforcing materials. Reinforcing materials are the most important factors to grant strength to a composite system and have different shapes. These materials are able to conduct heat and resist against chemicals. The applications of these materials are also very diverse and range from the manufacture of computer parts to tennis rackets and chemical storage tanks.

Fibers are the main component of fiber-reinforced composite materials. They occupy a significant volume of composite and bear a large portion of the load on the composite structure. The amount, type and alignment of fibers are important factors that can affect the following properties: 1) Specific gravity 2) Tensile strength and modulus 3) Compressive strength and modulus 4) Fatigue strength and failure mechanism 5) Heat and electrical transfer coefficients 6) Price

The reinforcing phase in the composite can be in the form of fibers and particles that can also act as fillers. The fibers can be mineral (glass fibers, carbon fibers, etc.), organic (Kevlar, polyamide, etc.), metallic (boron, aluminum, etc.), or natural.

Due to the wide range of applications of glass fibers, these fibers are discussed below. Glass fibers prepare in a variety of shapes and types, such as continuous or parallel strands, short chopped fibers, or woven coils. These fibers are produced by passing molten glass through a platinum crucible with very small holes. Immediately after the glass filaments leave the crucible, they are quickly cooled by blowing moist air whose temperature and humidity is controlled, as well as by spraying water, and then wrapped in different size and thickness on cylinders for later use.

Glass fiber is the most common and widely used fiber in the composite industry. They are divided into different types according to the type and composition of materials used in their preparation. The main constituent of glass fibers, like ordinary glass (Soda-lime glass), is silica (SiO2). Other oxides such as B2O3 and Al2O3 are added to modify the structure of the SiO2 network as well as to optimize the manufacturing process such as lowering the melting temperature.

The structure of glass fiber is a three-dimensional network of silicon, oxygen, and other atoms that are irregularly gathered together. Therefore, glass fibers have an amorphous structure, which is non-crystalline and isotropic. In isotropic materials the mechanical properties is the same in all directions.

Main advantages of glass fibers

It should be noted that these fibers show low tensile modulus, relatively high specific gravity, sensitivity to abrasion during transport (which often reduces tensile strength), low fatigue strength and high hardness which causes wear of molds and cutting tools.

Different types of glass fibers and their advantages

Glass fibers are classified as A, C, D, E, M and S.

The letter A refers to soda-lime glass and is derived from the word Alkali and is the ordinary glass that was common in the past which has poor thermal and chemical properties and is not suitable for the production of reinforcing fibers. The most common usage of this type of material is for making bottles, glass plates and soda glasses.

The letter C is derived from the word Chemical and is a fiber that has a very high chemical resistance.

The letter D is derived from the word Dielectric and is the fiber with the lowest dielectric constant. The lower the dielectric constant, the more transparent the substance is against electromagnetic waves. Therefore, these fibers are used in the construction of radar shields to protect the radar from atmospheric factors and pass the waves without dropping.

The letter E is derived from the word Electrical. These fibers show good electrical insulation properties. More than 90% of the glass fibers used in the composite industry are of this type. One of the most important capabilities of these fibers is its very high resistance to water, which is especially effective in the manufacture of composites used in humid environments.

The letter M is derived from the word Modulus and are fibers that have a high modulus.

The letter S refers to High Strength. The strength and price of this type of fiber is 20% and 4 times higher than type E, respectively. In addition, these fibers possess good tensile strength at high temperatures with significant resistance to wear. One of the most important applications of these fibers is in the aircraft parts as the engine shell of reactors and wherever there is a need for high efficiency.

The letter Z refers to fiber containing Zirconia and is a glass with excellent resistance to alkalis.

A noteworthy point about strands consisting of low-diameter fibers is that in the brittle fracture due to the growth of cracks, which can be due to the presence of fine cracks or surface flaws on the surface, only individual fibers are broken and the complete failure of the fibers is prevented. Therefore, a strand of fiber has a higher fracture strength than a fiber with a similar overall diameter. Because in a thick fiber the growth of a crack due to surface defects leads to its complete failure.

Affecting Factors on the strength of glass fibers

Studies show that the properties of glass fibers, in addition to the materials used in their structure, also depend on other factors such as environmental conditions. Other factors include the following.

A) Speed of loading: The strength of glass fibers increases with the speed of tension applied during the tensile test.

B) Temperature: The strength of glass fibers decreases with increasing temperature. For example, an increase in temperature from 20 to 100 °C is resulted in a 30% decrease in strength.

C) Moisture: The strength of glass fibers decreases with increasing humidity.

D) The ratio of the reinforcing phase to the matrix phase can have many effects on the properties of the composite. For example, tensile strength increases with increasing percentage of glass fibers, while elongation decreases. Therefore, an optimal limit is selected to obtain the desired characteristics.

Application of glass fibers

Electronics: GRP has been widely used to produce circuit boards (PCBs), televisions, radios, computers, cell phones, electric motor covers, etc.

Home & Furniture: Roofing sheets, bathtub equipment, windows, awnings, shelves, tea tables, hot tubs, etc.

Aviation and Aerospace: GRP has been widely used in aerospace, although it is not widely used to build the original aircraft framework, as alternative materials exist that are more appropriate. Typical applications of GRP are engine covers, luggage racks, toolboxes, caps, channels, storage buckets and antenna shields. It is also widely used in land shipment equipment.

Boat construction and marine applications: This material is ideally suited for boat construction. Although there have been problems with water absorption in the past, modern resins are more durable and are used to make simple boats. In fact, GRP weighs less than other materials such as wood and metals.

Medicine: GRP is widely suitable for medical applications due to its low porosity, non-staining and high wear resistance. From containers to X-ray boards (where X-ray transparency is important) it consists of GRP.

Car: GRP has been widely used in the production of auto parts such as body panels, seat covers, door panels, bumpers and engine covers. It can be said that GRP is generally used to replace metal and non-metal parts in various applications and its processing costs are relatively low compared to metals.

Introduction

Polyamides are high molecular weight polymers that have an amide group in their main chain which is considered as the main component of the polymer chain. The amide groups strongly adhere to each other and ensure high strength. These groups, which have become almost linear due to stretching, create strong hydrogen bonds with each other which are very strong.

Polyamides are classified into two groups according to their constituent monomers. 1) Polyamides that are prepared from the reaction of amino acids (AB) by the addition polymerization method. This method is used to prepare some AB type polyamides whose monomers are cyclic lactams such as ε-caprolactam or pyrrolidinone. 2) Polyamides that are formed from the condensation of bifunctional diamine and diacids that are called AABB type polyamides in which A indicates the amino group and B indicates the acidic group.

Aliphatic polyamides are named from the number that indicates the number of carbons in their constituent monomers. For AABB type polyamides two numbers are used. The first one refers to the number of diamine carbon atoms and the second one shows the number of diacid carbon atoms. Polyamide derived from ε-aminocaproic acid (6-aminohexanoic acid) or lactam is known as polyamide 6. Components with benzene rings are marked with a letter. For example, terephthalic and isophthalic acid are marked with T and I. Some authors also use TA and IA.

Linear polyamides are condensation products of bifunctional monomers. The hydrocarbon part between the amide groups may include branched or linear condensed hydrocarbons, aromatic rings or aliphatic rings, which can also include oxygen, sulfur and nitrogen. The hydrocarbon part used in the chain affects the flexibility of the chain and its structural arrangement, which is an important factor for the formation of the crystalline phase.

Aromatic polyamides are polymers in which an amide bond is placed between two aromatic rings. These polymers are prepared from the reaction of aromatic diamines with aromatic diacids in an amide solvent. Fibers with good heat resistance and high tensile strength and modulus are prepared from these polymers. Due to the unusual physical properties of aromatic polyamides, the general name aramid was chosen for them in 1974.

Aramid is a synthetic fiber made from long-chain polyamide in which at least 85% of the amide bonds (CONH) are directly attached to two aromatic rings.

In commercial aramids, 100% of amide bonds are connected to aromatic rings. With the creation of the new term aramid, synthetic fibers made from long-chain polyamide in which less than 85% of the amide bonds are directly attached to the aromatic ring were called nylon.

Properties

Polyamides comprise properties such as excellent toughness and impact resistance, excellent abrasion resistance, low friction coefficient, high tensile strength properties and optimal creep resistance, maintaining mechanical and electrical properties in a wide range of temperatures, excellent resistance to oils, greases, solvents and bases. These polymers can be processed through all special methods of thermoplastics.

Polyamide 6

It is obtained from polymerization of w-aminocaproic lactam, which is more famous under the name of caprolactam. For this reason, this plastic is also called polycaprolactam. Another chemical name of this compound is 2-oxohexamethyleneimine. By opening the caprolactam ring and the formation of a molecule with two very active ends and joining of these structural units by intercondensation and addition method, the polymerization is carried out and finally the aliphatic polyamide is obtained.

Thermal properties of polyamide 6

The properties of polyamide 6 are very similar to polyamide 66, but there are also differences between them in terms of thermal and mechanical properties. Tensile properties, hardness, thermal properties and density of polyamide 66 is superior to polyamide 6, so the toughness and impact resistance of polyamide 66 is higher than polyamide 6. Polyamide 6 shows high shrinkage after molding due to its semi-crystalline nature. The melting range of polyamide 6 is in the thermal range of 222°C, its glass transition temperature is 53°C and its long-term operating temperature is 90°C.

Polyamide 6 with the high molecular mass and high degree of crystallinity which is used in the casting method, shows improved mechanical and thermal properties compared to other molding methods. Its moisture absorption is also reduced and retains its positive characteristics against changes in humidity.

The table below shows the most important thermal characteristics of polyamide 6.

Mechanical properties of polyamide 6

Polyamide 6 possesses high strength and stiffness, high hardness, good stability against creep, good resistance to wear and thermal aging. Reducing the number of methylene functional groups in the structural unit of the polyamide 6 chain, makes this plastic benefit from a higher melting range of 220, more moisture absorption and higher mechanical properties compared to polyamide 11 and 12. Polyamide 6 fibers have high tensile strength and toughness, high elasticity and luster. These fibers are resistant to wrinkling and wear. Moisture absorption of polyamides, especially polyamide 6 and 66, causes a sharp decrease in their modulus because the presence of water between polyamide chains, which have high moisture absorption capabilities, makes them soft. Polyamide 6 fibers absorb moisture in 50% to 2.7% relative humidity condition, which this amount of water has a favorable reducing effect on its mechanical properties. The amount of moisture absorption of polyamide 6 fibers in saturated relative humidity (100%) is equal to 9.5-11%. The increase in moisture absorption causes a sharp decrease in the mechanical properties of the polyamide 6 products. As the temperature increases, the elastic modulus of the parts made of polyamide 6 decreases sharply.

In the table below, some of the most important mechanical and electrical properties of polyamide 6 are presented.

Different types of polyamide 6

Polyamide 6, like polyamide 66, contains a set of excellent properties, so it can be used in wide range of applications and diverse processes.

In the first and most important classification, polyamide 6 is divided into six groups: homopolymer, copolymer, alloy, improved, filled, and reinforced. In some of the polyamide 6 homopolymer due to the mixing with fluoroplastics at a weight ratio of 15%, 20%, 30%, a fluid-like state and reduction of friction for the final product is occurred.

Homopolymers: There are varieties of polyamide 6 homopolymer that have been developed for the injection process with low viscosity and high melt flow rate. Other types of polyamide 6 homopolymer are suitable for the extrusion process due to their high viscosity.

Reinforced: Reinforced polyamide 6 with glass fibers (long and short) are made in weight ratios of 10%, 15%, 20%, 30%, 40% and 50% to produce composite parts.

Improved: Using additives and with the aim of improving the properties and increasing the efficiency of polyamide 6, various types of this plastic have been supplied to the market, such as the types which are resistant to UV, containing softener or heat stabilizer, or with the higher degree of crystallinity and having a nucleating agent (clarifier). It is worth mentioning that the nucleating agent, in addition to making the product opaque and transparent, increases the speed of the molding and consequently improves the production efficiency. Several types of polyamide 6 have been made with molybdenum disulfide additive which can show excellent resistance to wear.

Filled: There are other types of polyamide 6 that have powdery mineral fillers such as gypsum or lime at 20% and 30% weight ratios.

Polyamide 6 copolymers: Several copolymers and terpolymers have been made from polyamide 6 that some of which have been commercially available for years. The most important polyamide 6 copolymers are 6/610 and 6/66. Copolymer 6/66 was provided by BASF, Germany, which its two comonomers has the ratio of 85:15.

Polyamide terpolymers 6/610/66: These are copolymers with high flexibility and ability to dissolve in water and alcohol (in a mixture), which have high impact absorption ability. Ultramid 1c terpolymer is made of polyamide 6. Terpolyamide include equal amounts of polyamide 6 and polyamide 66 and another amide compound called diaminodicyclohexylmethane. This terpolymer is used as a coating and finishing operation.

Typical applications of polyamide

Transportation: Transportation represents the largest market for polyamides. Applications of unreinforced materials include electrical connectors, wire coatings and lightweight gears, windshield wipers and speedometers. Stone guards and trim clips have been used to protect the windshield of the car. Glass-reinforced polyamides have been used in engine fan shrouds, radiator heads, steering and brake of fluid reservoirs and valves, sensors, and fuel injectors. Mineral reinforced resins have been used in mirror tools and tire hub covers. A combination of glass and mineral materials is used in exterior parts such as fender extensions.

Electrical and electronic applications: Flame retardant polyamides, including those that are performed with UL-94V0 requirements, play a major role in the electrical goods markets (plugs, fasteners or connectors, coils, wiring harnesses, terminal blocks, and antenna mounting tools).

Home Appliances: Polyamides are used not only for components in electrical goods, but also for mechanical parts and tools, power tools, washing machines, and various small household appliances.

Special applications in telecommunications: Power amplifiers or radio/telegraph amplifiers, amplifier stations, and connectors.

Industrial applications: Including hammer or sledgehammer handles, lawnmower parts, non-greased gears, bearings, anti-friction parts and a wide range of applications requiring spring clips or mounting the load on the spring.

Food and textile processing equipment: Including pumps, valves, measuring devices, agricultural and printing devices, office and sales machines.

Consumer Products: Applications of tough and toughened polyamide include ski boots, roller skates and ice skates bases, racket sports equipment, bicycle wheels, kitchenware, toys, and photography equipment.

Polyamide films: These films are used in a wide range for packing all kinds of meats and cheeses, as well as in non-stick bags for cooking and frying food. They are also used as an enclosing coating for making small airplane wings made of thermosetting polymers.

Wire and cable coating: Polyamides are often used as a protective layer on the primary insulation layer.

Piping and piping materials: Polyamides are used to transfer special brake fluids, special fluids for refrigerators, or as an inner lining for flexible cables.

Extrusion: sheets, bars, and handle-like shapes in machining.

This application includes filter bags for hot gases coming out of the chimney, under-press fabrics in industrial presses such as use in the permanent press of the final stage of linen fabric and linen polyester clothes, ironing board cover and sewing thread for very fast sewing, insulating paper for electric motors, tubes made for wire insulation, and dryer belts for papermaking. Another application is as pressure sensors in fuel tanks.

• Flame-resistant materials:

This application includes industrial protective clothing such as welders’ clothing and other protective clothing, firefighter clothing, flight clothing for military pilots and mail bags, carpets, curtains, sofas, fabric and cargo covers, boat covers and tents.

• Materials with dimensional stability

Fire hoses, V-belts, and power transfer belts made with high modulus aramid fibers such as Namax are examples of this application.

• Cases with very high strength and high modulus

These materials are used in V-belts of cables, parachutes, bulletproof vests, rigid reinforced plastics, antenna components, electrical circuit boards, sports equipment, ship ropes, telephone and power line cables, and fiber optic cables. Other usage is as a substitute for fireproof cotton.

• Cases with special properties

This application includes the fabrication of hollow fiber permeable separation membranes used for seawater and saltwater purification.

• Automobile industry

Polyamide 6 and polyamide 66 are used in the automotive industry. This industry accounts for 25% of the global consumption of polyamides.

In addition to making parts, polyamide 6 is also used in the production of a very large volume of textile and non-textile fibers. Due to its linear structure, fibers with particular properties are obtained from this resin.

Polyamide 6 has a wide range of applications in the manufacture of products that comprise high strength, wear resistance, high hardness and resistance to thermal wear, or the part has the ability to be machined.

This plastic is used in making gears, bearings, connections, fibers, car parts, all kinds of films, and films used for food packaging. Polyamide 6 is also used in making the collar of wheelchairs, propellers, strings of musical instruments such as violin, guitar, viola, cello, sitar, and etc.